Introducing the STUBBI® Cove Rollers

The STUBBI® is a groundbreaking tool designed to redefine the art of cove forming in the flooring trade. Engineered specifically for the demands of commercial flooring, the Stubbi® combines durability, precision, and adaptability to meet the toughest challenges of its environment. It’s over-engineered to go the distance and has quickly become an essential tool for vinyl installers worldwide.

Why Choose the STUBBI®?

The innovative design of the Stubbi® surpasses conventional hand rollers by introducing a dual-radius profiled head, a world’s first in lateral pressure contact for cove forming. This cutting-edge feature is smoothly supported by twin ball bearings, ensuring effortless movement and unmatched precision during use.

Key Benefits

Uncompromising Support: The Stubbi® ensures coved floor coverings are fully supported by a solid backing, adhering to industry best practices and eliminating liability for movement between connecting components.

Enhanced Adhesion: By embedding the cove fillet deeply into the juncture, the Stubbi® ensures full contact adhesion of sheet material and the cove fillet, even at the curvature of the cove riser—the vinyl's weakest point.

Durability in Action: Designed with the harshest environments in mind, the Stubbi® is built to withstand the rigors of commercial use, making it a long-term investment for professionals.

Pre- and Post-Rolling Precision: The pre- and post-rolling process guarantees that the vinyl adheres fully and firmly, removing any potential for perimeter weaknesses caused by movement.

Setting a New Standard

The Stubbi® is more than just a tool—it’s a game-changer in the world of flash coving. By combining innovation with practicality, it enables installers to meet and exceed manufacturer recommendations while delivering superior results that stand the test of time. Join Preferred Flooring in Setting the Standard, One Installation at a Time!

CLICK HERE TO BUY NOW

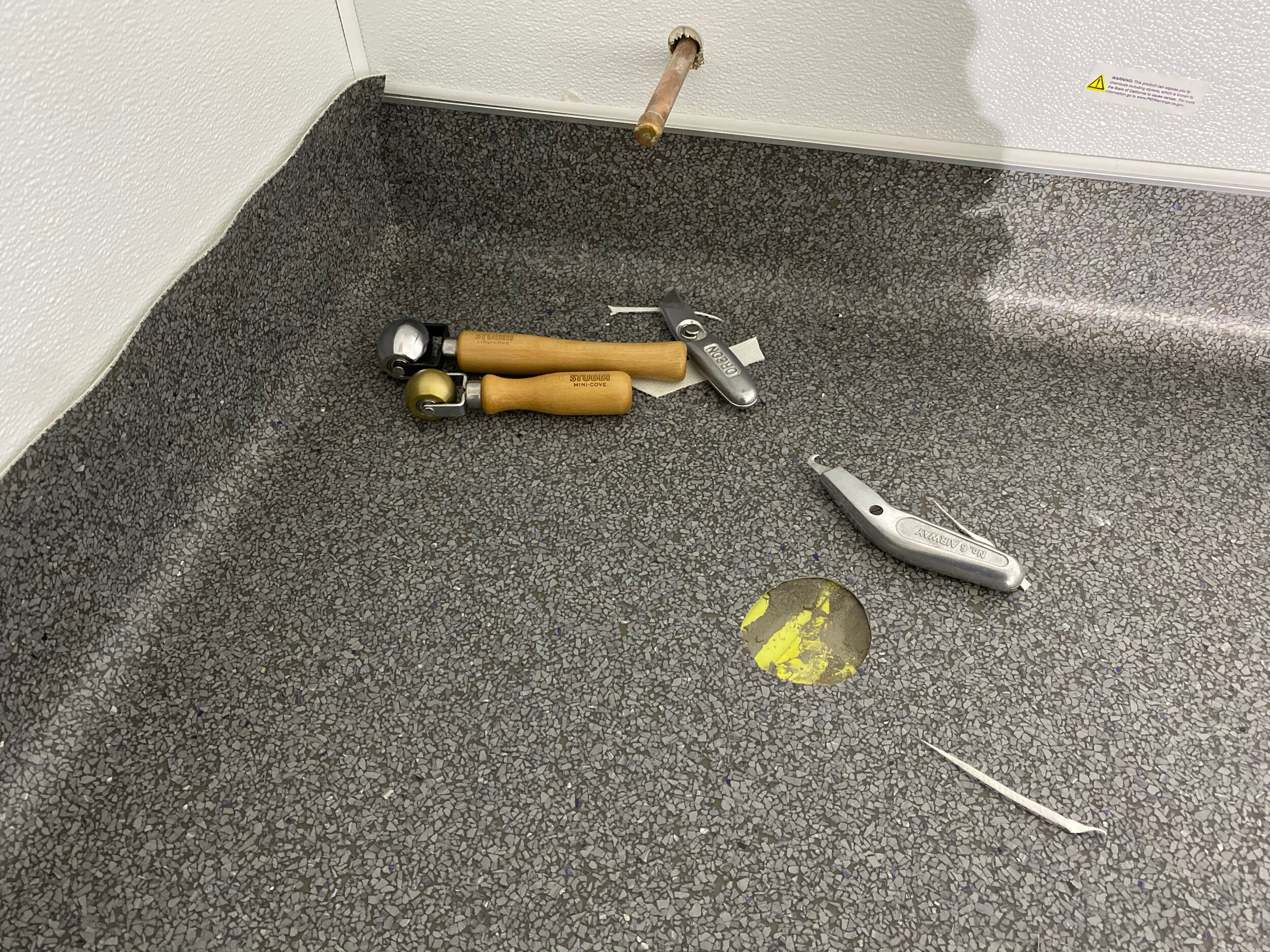

The STUBBI® Lineup

The Stubbi® is available in four versatile sizes, each designed to tackle specific challenges in flooring installation:

1 1/8” Brass/Steel Orb – Mini Cove Roller - Size 6 7/8” x 1 1/2” x 1 9/16” - Weight - 11.5oz

1 3/4” Zinc-Plated Steel Orb – Lino Cove Roller - Size 9 1/2” x 1 3/4” x 2 3/32” - Weight - 1lb 1.8oz

Custom Zinc-Plated Shape – Capp Roller - Size 7 1/4” x 2 3/8” x 1 3/4” - Weight - 1lb 1.8oz

1/4” Brass/Steel Wheel – Edge Roller - Size 7 1/4” x 2 1/2” x 1 1/2” - Weight - 7.1oz

Built Tough for Professionals

Designed by seasoned installers in Australia’s Northern Territory, the Stubbi® is built to withstand the toughest environments while delivering unmatched precision and results.

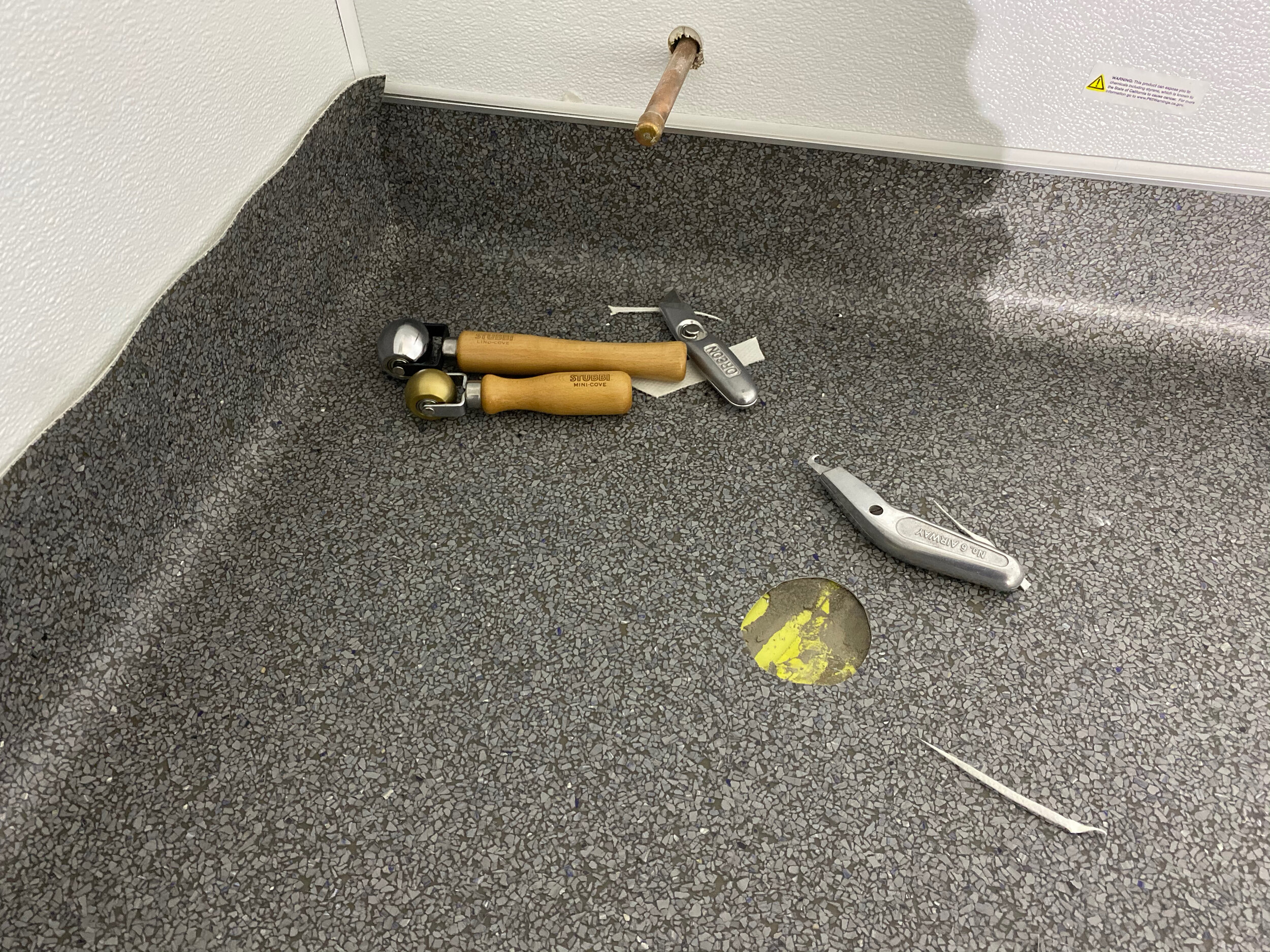

Eliminate Cove Cracking with STUBBI® Rollers

When it comes to cove installations, traditional tools often fall short in ensuring durability and precision. Foot traffic and furniture near the cove are leading causes of installation failures, resulting in cracking and compromised adhesion. That’s where the STUBBI® Rollers come in—they’re not just tools, they’re essential for getting the job done right the first time.

The STUBBI® Rollers are specifically designed to address these challenges, providing unmatched precision and reliability. Without them, you risk weak points in the installation that can lead to costly repairs and dissatisfied clients.

FThe STUBBI® Solution: A Simple 3-Step Process to Eliminate Cove Failures

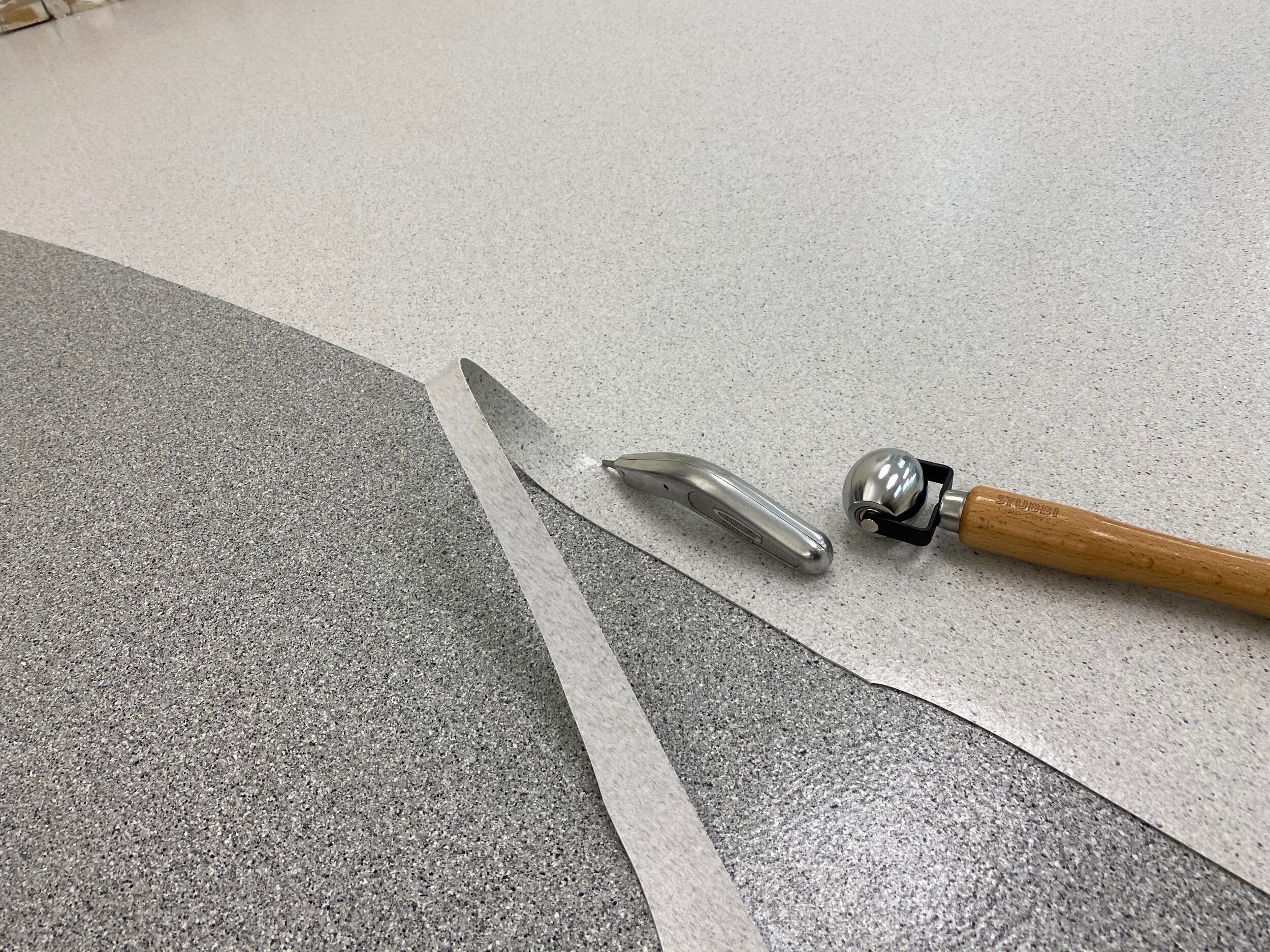

Pre-Roll

Use the Stubbi Roller to firmly roll the coving strip into the adhesive at the wall and floor juncture. This ensures a solid bond from the start, setting the foundation for a flawless installation.Installation

Stubbi Rollers apply precise lateral pressure to securely bond the vinyl sheet to the cove former strip at the base level. This step guarantees the integrity of the connection, removing the liability of movement between components.Post-Roll

The finishing touch: Stubbi Rolling the installed vinyl product neatly into the curvature and wall risers. This step ensures complete contact adhesion, eliminating weak points and delivering a professional finish that lasts.

Why STUBBI® is Essential

Without the STUBBI® Rollers, installations are left vulnerable to:

Cracking at the Cove: Weak bonds and incomplete adhesion at the wall-floor juncture are common with traditional tools.

Damage from Foot Traffic and Furniture: Improperly installed cove areas are prone to wear, tear, and costly repairs.

With the Stubbi®, you ensure:

Uncompromising Precision: Every inch of the cove is rolled to perfection, adhering to the highest standards.

Enhanced Durability: Prevent movement and cracking, even under heavy foot traffic and furniture pressure.

Superior Results: A flawless, professional-grade finish that stands the test of time.

The STUBBI® Rollers are not just an upgrade—they’re a necessity for installers who refuse to compromise on quality. Don’t risk cove failures—equip yourself with the tool that ensures precision, durability, and perfection on every installation.

Join Preferred Flooring in Setting the Standard, One Installation at a Time